Archive for February, 2019

The Best of the Best – Toyota Genuine Parts

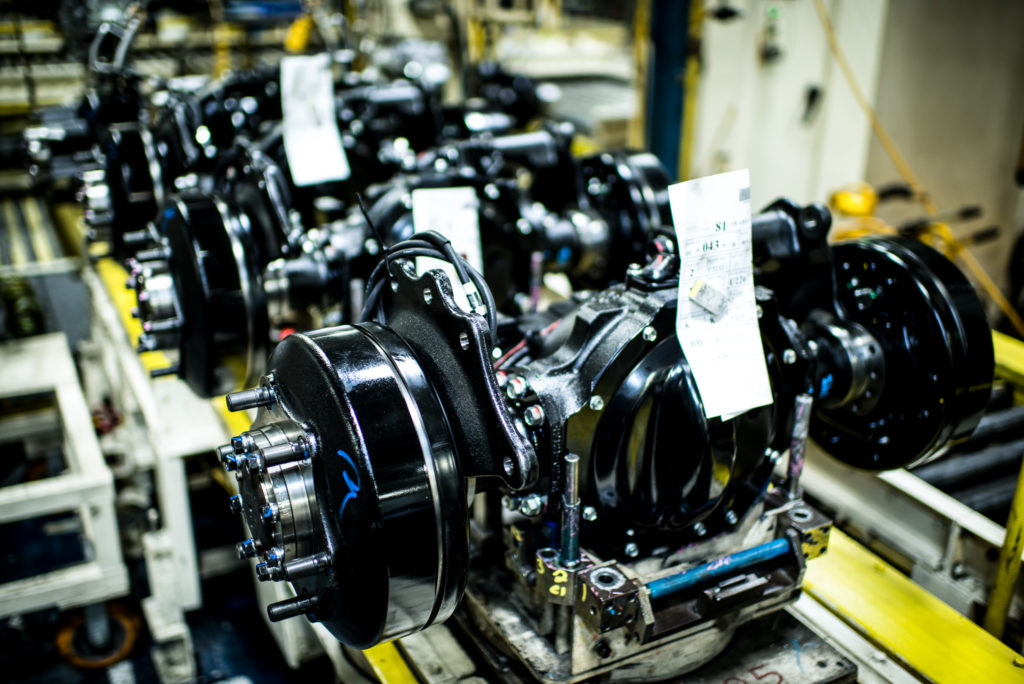

The best way to maximize the value of your Toyota Forklift is by replacing its parts with the originals. Spare parts seem like a commodity you purchase without much thought, but innovative operations know that the parts make up the whole. With Toyota Genuine Parts, you may pay more upfront but also benefit from its quality, durability, reliability, and long-term value.

When you purchased your Toyota Forklift, you did so because you are aware of its quality, and you are aware of Toyota’s performance reputation. Toyota Genuine Parts have the same quality, care, material, and attention to detail as Toyota forklifts.

Toyota Genuine Parts are durable, and reliable, and you won’t have to worry about your forklift not working as hard as you do. They will help you increase your uptime and keep you running longer because Toyota Genuine Parts are made to work and last.

The Best Forklift Spare Parts are Guaranteed by our Industry-Leading Warranty

Toyota Material Handling Solutions will help with a replacement or repair of any Toyota part that is defective under normal use within a two-year or 4,000-hour time frame. A Toyota Genuine Part is covered for two years or 4,000 hours from the date of purchase or installation. Most importantly, Toyota Material Handling Solutions of Los Angeles will not charge for warranty repair or replacement work done during that time. If a Toyota Certified Technician performs work, and labor, there is no charge for warranty repair or replacements.

Until they can assure the highest quality work, trainers will not allow a technician to come work on your Toyota Forklift. Our Toyota Certified Technicians undergo extensive training, including hours of classroom and field-supervised training. During this training process, technicians use Toyota Genuine Parts. These parts are the foundation of their education. A Toyota Certified Technician will know every part of your forklift model, inside and out. By using the best spare parts for your forklift, you get the best possible work, helping you with your uptime and the overall success of your business.

Operations that Order the Best Forklift Spare Parts Increase Uptime

In the material handling industry, we strive for uptime. More work is getting done when we’re in uptime, and we’re sure you can benefit from the same.

Dependable, long-lasting parts will keep your fleet running. Toyota Genuine Parts work correctly with other components in your Toyota Forklift. Using Toyota Genuine Parts as your replacements, you are upgrading your equipment and uptime.

Customers like it when their orders come in quickly. Uptime means there will be no delays. When customers demand things to be completed quickly, you risk gaining a reputation for delivering items slowly. By always having working equipment, you gain uptime that helps save your reputation. When you’re in uptime, your employees can do their job correctly because the tools they need work efficiently. You’re also not continually waiting on downed equipment, which gives you more time for necessities and improvements and a chance to be more innovative.

WE CARRY FORKLIFT SPARE PARTS THAT ARE COMPATIBLE WITH OTHER MANUFACTURERS

With our StarLift Program, Toyota Material Handling Solutions is always your one-stop shop, even when you have a mixed fleet. StarLift is a parts program that helps complement Toyota Genuine Parts. The program makes forks, oils/chemicals, batteries, tires, and other replacement parts for mixed-fleet customers. The forks the StarLift program offers are the same ones that come standard on your Toyota Forklift.

Call us today at (866) 794-5438 if you have questions about how Toyota Genuine Parts can help your uptime!

What Are Critical Spare Parts?

Keeping too large of an inventory of spare parts on hand can hinder both your budget and the physical operating space of your business. But what happens if your forklift goes down and you don’t have the necessary parts available? Your business can suffer from unnecessary downtime, and you may be forced to overpay to have the parts shipped to you overnight.

Keeping too large of an inventory of spare parts on hand can hinder both your budget and the physical operating space of your business. But what happens if your forklift goes down and you don’t have the necessary parts available? Your business can suffer from unnecessary downtime, and you may be forced to overpay to have the parts shipped to you overnight.

The easiest solution is partnering with Toyota Material Handling Solutions and having us handle all of your service needs. We offer a variety of maintenance plans to protect your investment — ranging from monthly planned maintenance programs that include safety inspections and routine maintenance to comprehensive plans like our VMS full maintenance programs that cover planned maintenance and breakdowns, including parts and labor.

If you prefer to perform your own maintenance and repairs; and are looking to define a critical spare part, ask yourself the following:

Which parts do you purchase most often? This should always be your first consideration, especially if you maintain a fleet of several forklifts. You’ll need to determine which parts you most consistently replace and make sure you keep them in your on-site inventory.

Which parts do you purchase most often? This should always be your first consideration, especially if you maintain a fleet of several forklifts. You’ll need to determine which parts you most consistently replace and make sure you keep them in your on-site inventory.- If your forklift goes down, how quickly will you need the part? If your answer is immediately, then it is a critical part. If you have a back-up forklift on hand or another solution to covering the downtime, it is not a critical part.

- Will your business suffer if you don’t have the part? If the answer to this question is yes, then it is a critical part and must be kept in your inventory.

- How long will it take to receive the part if ordered? Find out which parts Toyota Material Handling Solutions has on hand and which parts need to be ordered. If ordering a part on the spot will take too long, it is critical to have that part on hand in case of an emergency.

Have a Backup Plan

Keep a list of those critical parts so that your technicians will always know what steps are needed to be taken in order to obtain those parts.

Keep a list of those critical parts so that your technicians will always know what steps are needed to be taken in order to obtain those parts.- If you are going to experience lengthy downtime, Toyota Material Handling Solutions has an extensive inventory of short term rental forklifts.

By being prepared and determining which parts are critical to your operation, your business could save money and most importantly, time.

Our specialists at Toyota Material Handling Solutions are here for you if you need more information on how to determine which parts are critical to your operation. Call us today at (800) 794-5438!

The Toyota Value Story

Engineering

Engineering and innovation excellence are Toyota trademarks when it comes to forklifts. Each part, component, or attachment in a Toyota forklift is designed to help increase productivity and uptime. Toyota Genuine Parts are designed with quality to extend the life of your forklift. You can trust our Toyota Certified Technicians to get the most out of your forklift.

Engineering and innovation excellence are Toyota trademarks when it comes to forklifts. Each part, component, or attachment in a Toyota forklift is designed to help increase productivity and uptime. Toyota Genuine Parts are designed with quality to extend the life of your forklift. You can trust our Toyota Certified Technicians to get the most out of your forklift.

Long-Term Value of Toyota

All Toyota forklifts have the opportunity to be strong assets. With proper care, they will last for many years. If you plan on using your new forklift indefinitely, you may decide that purchasing is the best way to go, or you can decide to take advantage of Toyota Commercial Finance lease, for something more short-term. Both long and short-term options are available to provide solutions to customers across. Toyota Material Handling Solutions is one of the best in the business and a Toyota Certified Technician is only a call away. We’re interested in your business and your needs, and through our world-renowned Toyota Production System and Delivery Experience Program, we hope to be a valuable partner for life.

All Toyota forklifts have the opportunity to be strong assets. With proper care, they will last for many years. If you plan on using your new forklift indefinitely, you may decide that purchasing is the best way to go, or you can decide to take advantage of Toyota Commercial Finance lease, for something more short-term. Both long and short-term options are available to provide solutions to customers across. Toyota Material Handling Solutions is one of the best in the business and a Toyota Certified Technician is only a call away. We’re interested in your business and your needs, and through our world-renowned Toyota Production System and Delivery Experience Program, we hope to be a valuable partner for life.

Competitive Pricing

Sales price is only one factor in the equation when comparing Toyota Forklifts. With Toyota’s performance, quality, and engineering in mind, you can reject products that look like but are of lower quality. When dealing with downtime, cheaper options are not the right choice. Since 2002, Toyota forklifts have been top-selling worldwide. We consistently rank the highest quality, reliability, durability, safety, and value rates.

Sales price is only one factor in the equation when comparing Toyota Forklifts. With Toyota’s performance, quality, and engineering in mind, you can reject products that look like but are of lower quality. When dealing with downtime, cheaper options are not the right choice. Since 2002, Toyota forklifts have been top-selling worldwide. We consistently rank the highest quality, reliability, durability, safety, and value rates.

Call us today at (866)794-5438 to get a quote on the Toyota forklift you’ve been eyeing for your business!

Valuing the Toyota Production System

For decades, Toyota has been a leading supplier of innovative forklifts –– one in every five forklifts around the world is a Toyota. The quality, durability, reliability and overall value of a Toyota Forklift, is what makes it so highly regarded. This is a result of the Toyota Production System and lean manufacturing. It’s our foundation for success and reason for your purchase of a Toyota forklift, ensuring that you’re getting the highest quality product on the market. Let us show you what quality, durability, reliability, and overall value means to us:

For decades, Toyota has been a leading supplier of innovative forklifts –– one in every five forklifts around the world is a Toyota. The quality, durability, reliability and overall value of a Toyota Forklift, is what makes it so highly regarded. This is a result of the Toyota Production System and lean manufacturing. It’s our foundation for success and reason for your purchase of a Toyota forklift, ensuring that you’re getting the highest quality product on the market. Let us show you what quality, durability, reliability, and overall value means to us:

Quality: Kaizen, one of Toyota’s philosophies, is the concept of always improving the quality of its products. Employees at Toyota’s production facilities are encouraged to offer suggestions to better improve the processes and production of all Toyota Forklifts. A 2015 study conducted by Peerless Research ranked Toyota Forklifts number one in quality for 11 years in a row!

Durability: A Toyota Forklift owner stated they have ten Toyota trucks, each with 20,000 hours or more, and they still run with excellent run time and minimal downtime. Toyota Forklifts are manufactured to stay strong and keep running!

Reliability: Toyota forklifts may get a lot of use, but they are designed to need less maintenance and to be more energy efficient than other brands. A regular preventative maintenance plan is all a Toyota fleet needs to keep running.

Value: With environmentally-friendly and fuel efficient forklifts, Toyota gives you multiple ways to boost your savings! Toyota ranked number one for both value and for the lowest cost of ownership, in the study mentioned above, for 11 years in a row.

The Toyota Production System and lean management philosophy is founded on a set of principles –– all built on practice, striving for improvement, and people dedicated to success. They include the following:

Challenge: Maintaining a long-term vision while courageously and creatively meeting all steps towards realizing that vision.

Kaizen: Continuous Improvement. There is always room for improvements, no process is ever declared perfect.

Genchi Genbutsu: Going to the source to find the facts, allowing you to make correct decisions, build consensus, and achieve goals.

Respect: Always respect others. Build mutual trust, accept responsibility, and make an effort to understand others.

Teamwork: Maximize individual and team performance, by sharing opportunities for development and stimulating individual/team performance.

How does Kaizen lead to success in the Toyota Production Systems?

Kaizen identifies problems at their source and involves all employees making improvements on a continuous basis. Kaizen can make a difference at your company in 3 ways –– by reducing waste, giving immediate results, and improving employee retention.

Kaizen identifies problems at their source and involves all employees making improvements on a continuous basis. Kaizen can make a difference at your company in 3 ways –– by reducing waste, giving immediate results, and improving employee retention.

It can reduce waste in areas such as overproduction, worker movement, waiting times,

and inventory. Continuous small changes are usually easy to apply, giving you immediate results. Kaizen also gives employees a greater responsibility for their job by including them in the process, resulting in higher employee morale and job satisfaction.

Toyota’s 5S Approach

Implementing Toyota’s famous 5S philosophy can easily be applied to a wide variety of industries, not just manufacturing. The 5S approach to organization and workplace culture is one of the main reasons lean management works, and it can happen at your facility. These 5 steps will help you get started:

Seiri (Sort): Separate necessary items from unnecessary.

Seiri (Sort): Separate necessary items from unnecessary.

Seiton (Straighten): Make a place for everything. Everything must have a proper place.

Seiso (Shine): Maintain a clean work environment. Clean up as you work.

Seiketsu (Standardize): Develop rules that will repeat positive results.

Shitsuke (Sustain): Strive for continued improvement and maintain consistency.

If you’d like to learn more about the value of the Toyota Production System and the ways in which it can benefit your operation, call us at (866) 794-5438!