Have you wondered if the principles of Toyota Lean Management (TLM) could apply to your business? There is much information on the subject in books and the internet, but why go elsewhere when you can get your information directly from the source – Toyota!

Many years ago, Toyota created the Toyota Production System (TPS), a philosophy that organizes manufacturing and logistics at Toyota, including its interaction with suppliers and customers. TPS is also frequently called “lean manufacturing.”

Three top Toyota executives influenced TPS/Lean Manufacturing: founder Sakichi Toyoda, his son Kiichiro Toyoda and Toyota chief engineer Taiichi Ohno. The system’s main goal is simple – to eliminate waste, called “Muda.”

We sorted through the abundance of information on the Toyota Forklifts website to curate three articles for those just starting to learn about the principles of Lean Management.

The first article, titled “What is Toyota Lean Management?” is a great place to start.

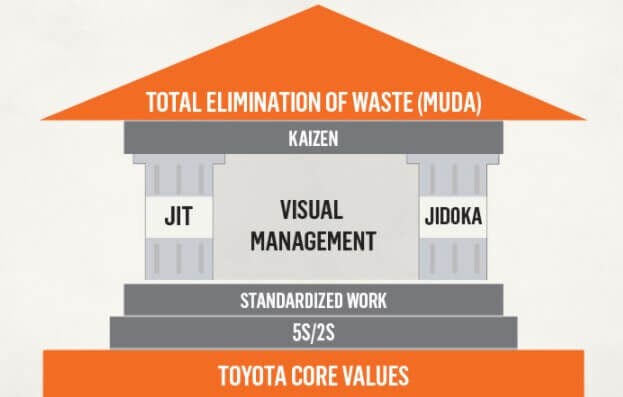

The article explains the elements necessary to build a strong “house” using Toyota Lean Management (TLM). You’ll learn about a critical component for a strong TLM foundation, a five-step system called 5S. The principles of 5S can be applied to any business setting, manufacturing/factory setting, or even your personal life to help organize your home and practices.

You’ll also learn the importance of developing a culture of respect encouraging innovation and development, the Lean Management Pillars: Just-in-Time and Jidoka, and the elements necessary to build the support beams and roof to complete your “house.”

The following article is titled “Benefits of Lean Management Practices.” You’ll learn the three benefits of lean management techniques here.

Finally, we suggest you read “How to Get Started on Your Lean Journey.” This article details four specific steps you should take to get started.

Toyota Lean Management is both a process and a mindset. Our experts can walk you through the process and offer valuable advice to increase productivity and efficiency throughout your company. Contact us today if you’d like to lean on us (pun intended) to help you implement Toyota Lean Management practices in your operation.

Tags: free resources, lean maintenance, toyota production system