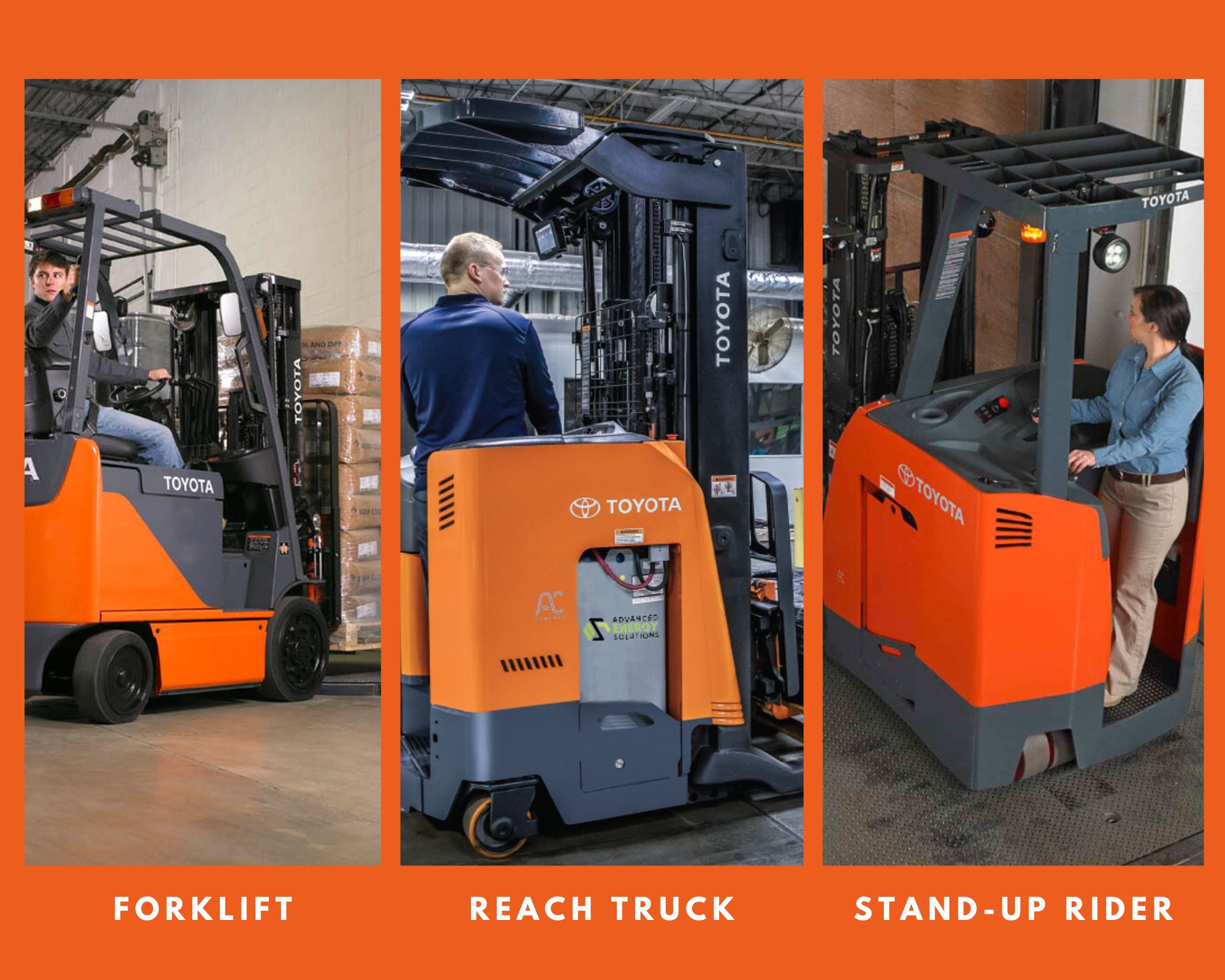

When efficiency is the key to success, choosing the right equipment is essential. Forklifts, reach trucks, and stand-up riders are commonly used in warehouses and distribution centers. While they may seem similar initially, they serve distinct purposes and excel in specific applications. In this blog post, we’ll explore the differences between forklifts, reach trucks, and stand-up riders and help determine your needs.

Forklifts

Forklifts are workhorses of the warehouse and industrial world. They are versatile and can be used in various applications, making them a staple in many workplaces. Here are four key features and applications of forklifts:

- Lifting Capacity: Forklifts are known for their impressive lifting capacities, capable of handling heavy loads ranging from 3,000 to 36,000 pounds or more, depending on the type and model.

- Lifting Height: Forklifts typically lift loads to lower heights, making them ideal for applications where items are moved on and off pallets or loaded onto trucks.

- Maneuverability: Forklifts are designed for maneuverability in tight spaces, making them suitable for indoor use in warehouses, manufacturing facilities, and distribution centers.

- Fork Length: Forklifts feature longer forks, which allow them to easily slide under pallets or other heavy objects for efficient lifting and transport.

Reach Trucks

Reach trucks are for more specialized applications, particularly for lifting and transporting palletized loads in narrow aisles or racking systems. Here are four key features and applications of reach trucks:

- Lifting Capacity: While reach trucks are not as powerful as forklifts, they still offer substantial lifting capabilities, often ranging from 2,500 to 5,000 pounds.

- Lifting Height: The standout feature of reach trucks is their exceptional vertical reach. They can lift loads to heights of 30 feet or more, making them perfect for high-density storage in narrow aisles.

- Maneuverability: Reach trucks are for precise handling in confined spaces. Their ability to navigate narrow aisles and tight corners makes them the preferred choice for efficiently using vertical storage space.

- Fork Length: Reach trucks have shorter forks than forklifts, explicitly designed for accessing pallets in narrow racking systems.

Stand-Up Riders

Stand-up riders, also known as stand-on forklifts, are versatile for various material handling tasks. Here are their key features and applications:

- Lifting Capacity: Stand-up riders typically offer a lifting capacity similar to traditional forklifts, making them suitable for handling medium to heavy loads.

- Lifting Height: While they may not reach the same heights as reach trucks, stand-up riders can lift loads to significant heights, often exceeding 20 feet.

- Maneuverability: Stand-up riders balance maneuverability and capacity, making them versatile for indoor and outdoor use. They are convenient in busy warehouses and distribution centers.

- Operator Position: The operator stands on the platform of a stand-up rider, offering a better view of the surroundings and improved ergonomics during extended use.

When to Choose One Over the Other

Now that we’ve explored the characteristics of forklifts and reach trucks, let’s discuss when you might need one over the other:

Choose a forklift when:

- You need to handle heavy loads that exceed 5,000 pounds.

- Your primary task involves loading and unloading goods at ground level or within a warehouse.

- Maneuverability in narrow aisles is not a significant concern for your operations.

Choose a reach truck when:

- You require high-density storage in narrow aisles or racking systems.

- Your lifting needs focus on accessing goods at significant heights.

- Precise maneuverability in confined spaces is crucial to your operations.

Choose a stand-up rider when:

- You require versatility in both indoor and outdoor environments.

- Handling medium to heavy loads is part of your daily tasks.

- Operators need an elevated view for better visibility and ergonomics.

Understanding the differences between these three products will help you make an informed decision for your material handling operations, ultimately improving productivity in your workplace.

Are you still trying to decide which one is right for your application? Our industry experts can help you make the right decision. We also recently teamed up with Advanced Energy Solutions to help with various services, including forklift power options, battery maintenance systems, preventative maintenance services, and more. h more. Contact us to speak with an expert today.