When companies run out of space to store products, they have two choices: buy or lease a new building or warehouse or better utilize the current space. Many factors are involved when a company decides which to choose, but narrow aisles are often the more cost-effective long-term solution.

Here are three significant benefits of optimizing a warehouse, distribution center, or other space:

- Store more products in the same amount of space

- Increase fulfillment times with less travel time in between picks

- Minimize the total cost of doing business

The first step in optimizing a warehouse often includes reconfiguring to include narrow aisles. The next step is to use the most efficient forklift for the new narrow aisle space.

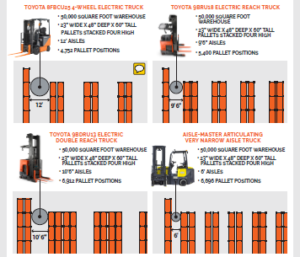

Let’s look at four ways to configure a 50,000-square-foot warehouse with pallet racking 23 inches wide, 48 inches deep, and 60 inches tall. Each rack holds pallets stacked four high.

In these four examples, you’ll see how narrowing the aisles and using the correct type of forklift can increase the number of pallet positions in the same amount of space.

In the first example, the aisles are 12 feet wide with single-deep pallet racking. This configuration can store 4,572 pallets with a Toyota 4-Wheel Electric forklift.

Aisle width: 12 feet

Pallet positions: 4,752

Forklift: Toyota 4-Wheel Electric

In the following example, the aisles are 9 feet, 6 inches, with single-deep pallet racking. This configuration can store 5,400 pallets with a Toyota Electric Reach Truck.

Aisle width: 9 feet, 6 inches

Pallet positions: 5,400

Forklift: Toyota Electric Reach Truck

In the third example, the aisles are 10 feet, 6 inches wide, and utilize double-deep pallet racking. This configuration can store 6,912 pallets with a Toyota Electric Double Reach Truck.

Aisle width: 10 feet, 6 inches with double-deep pallet racking

Pallet positions: 6,912

Forklift: Toyota Electric Double Reach Truck

In the last example, the aisles are 6 feet wide with single-deep pallet racking. This configuration can store 6,695 pallets with an Aisle-Master Articulating Very Narrow Aisle Truck.

Aisle width: 6 feet

Pallet positions: 6,695

Forklift: Aisle-Master Articulating Very Narrow Aisle Truck

Our experts can help optimize site productivity and minimize the total cost of ownership by synchronizing racking, conveyors, storage containers, and handling equipment. The results create the ideal material handling footprint to achieve a company’s operational goals.

To learn more about different pallet racking systems, click here. To learn more about optimizing your warehouse with Toyota, click here.

Ready to get started designing your new warehouse space? Contact us today!

Tags: warehouse solutions